We would like to get an inside look at how different roles contribute to Mujin’s success. Today I sat down with Denys, a lead robotics engineer. He is one of the first engineers to have joined us and knows a lot about the early days of Mujin.

– Can you tell me a bit about your background?

I was born in Ukraine, and both of my parents are engineers. My engineering journey started in my childhood. My parents gave me a book on how to program, and there was an illustration of how to program robots, which is how I chose my future. I decided to build my career in software development, and later in robotics engineering.

I got my bachelor degree in computer science at the National Technical University of Ukraine (KPI).There are no robotics engineering degrees available in my country, therefore I was looking for outside opportunities.

I moved to Paris learn more about science and to get my Master’s degree in computer science there. I studied at École Normale Supérieure (ENS Ulm), which is one of the most prestigious graduate schools in France. I finally could take robotics coursework and I understood the best application of my software development skills. I decided that I wanted to move huge machines so that they can help people and liberate them from hard labor.

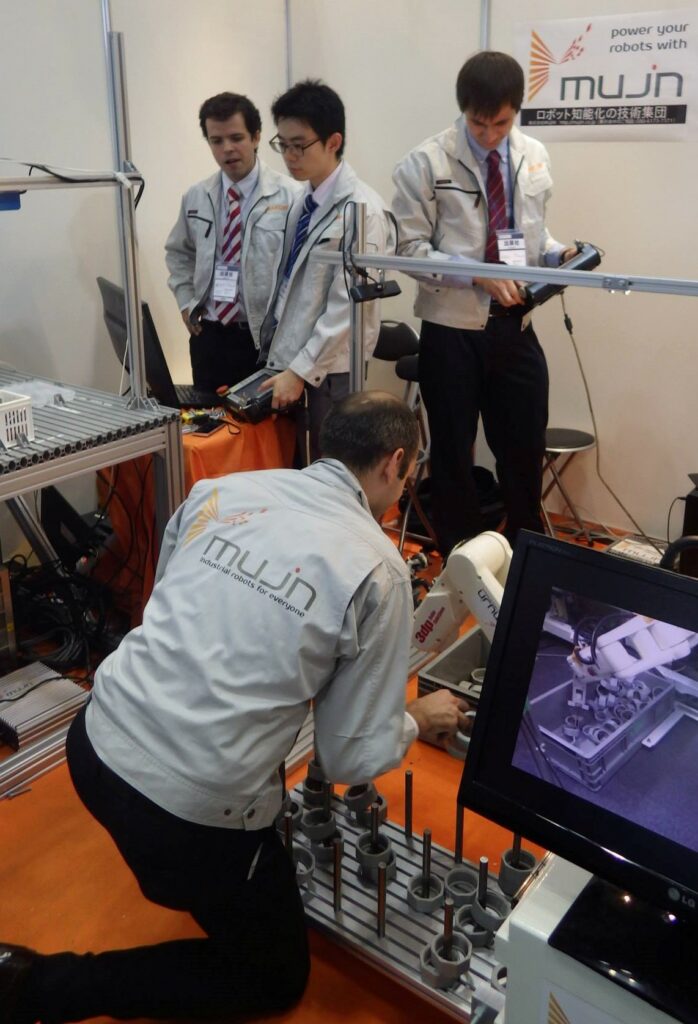

My graduation program included 2 long internships. For my first long internship, I asked my professor in robotics class, Jean-Paul Laumond, about companies where I could have an internship and study robotics. One of his suggestions was Mujin, the company which would change my future. Mujin attracted me because Japan is a mecca for automation and robots. That’s why I had no doubts about accepting the internship offer, which would lead me to come to Japan for 5 months in 2014.

At the time, Mujin was a tiny startup company. Our office was in a small garage on the 1F, and I was living just above it on the 3F. I was lucky; going to the office took me less than 1 minute. The company had only 4 people (Mujin story #3: Mujin power is Mujin people). It was hard to accomplish various tasks with only a small number of employees. It was a team of talented people who gathered and enthusiastically took up challenges in this difficult path.

I decided to sign a contract for a full-time position right after my internship.

I was so impressed by Mujin, by the passion and the commitment of people there, and how we were united by the same goal of delivering robotics to society.

– What do you think of Rosen?

Rosen is a “working engineering machine.” Before coming to Japan, I’ve never seen people working so hard to reach the goal. Rosen is an extremely smart engineer who has an understanding of everything. Whenever I have a question he always knows the answer, or we find a solution together.

At the same time it’s not like in other companies when a CTO, a company owner, or lead engineer just gives tasks to subordinates. This is not Rosen’s style. He always tries to help you and lead you through the problem to make things happen and solve the problem. That’s why I’m working with him.

– What is your team’s responsibility?

In the Robotics System Team we are responsible for our products. We take care of everything related to the robots, from parsing tasks for the robot such as parameters, customers’ requests, items to be picked; then taking data from the vision side, doing planning, figuring out how to move a robot, and how to achieve the task. At the same time, we have to take care of how to send trajectories, commands to the robot and other hardware, tracking feedback from the robot, and maintaining proper communication with the robot.

Evaluating and adding new devices (like force-torque sensors, hand control, etc.) is also one of the jobs in the robotics system team. Everything related to robot motion is a part of our responsibilities.

– Why is Mujin appealing to you?

I chose Mujin to work with super-smart people united by the same goal and working hard to achieve this goal. I think all our engineers are like that; we see the goal, which is to liberate humans from laborious work, and we are “blinded” by this goal to achieve it. We are an international community who want to achieve something real.

I can see huge progress compared to 5-6 years ago, and we will progress much more in the next 2-3 years. We are growing, having more talented people, becoming recognized by society, other companies, and engineers, and getting better representation on the market. We make a big splash no matter what we do.

– Is it challenging to work at Mujin?

There are always challenges. As I’m in a lead position now, I have a lot of responsibilities for projects. Most of our middle or senior engineers are responsible to deliver features for projects, which are always very critical for customers and real production lines.

We are moving 2-3 ton machines which can grab 200 kilos easily and move fast. If something goes wrong, these machines could easily damage themselves, workpieces, and people. Knowing this, our challenge is to achieve high quality in our work.

At the same time, when you achieve the challenge or goal, you get satisfaction and feel a sense of real accomplishment. We make a real impact on society compared to, for example, editing the button on the website. Our accomplishment makes me feel happy.

It’s a job where you can work with smart people, get lots of knowledge and experience from them, and study by yourself. We have enough resources here to get any hardware and test new features in our laboratory, check some assumptions or methods, and verify it on real hardware. We are customer delivery-oriented, and that’s where we get knowledge about how to use the technology.

Even if the technology is here, you cannot apply it in reality immediately. There is a huge gap between science and engineering. At Mujin we are closing this gap in robotics automation.

– Tell me about the most memorable work you did?

It happened during my internship. I didn’t expect a 5-kilogram payload robot could generate so much force. At that time we didn’t have the recovery mechanisms which we have now, and the system was not adapted for real execution. We had a slight collision of a robotic hand with a metal workpiece, and the robot motors stopped and turned on the brakes by alarm. The problem was that when we decided to turn on the motors, they went immediately into alarm mode because of the reactive force from the part. We had to loosen bolts from the robot arm to release the force and turn on the motors.

Nowadays, we have many recovery procedures, and this situation doesn’t happen anymore.

Another memorable event was when we delivered my first palletizing project to the customer. The moment you see how robots start picking real items and realize that people are not needed anymore to handle 20-kilogram boxes by themselves, you feel satisfied. You understand your hard work liberated some people from manual labor.

– I know you are a hiring manager. Which skills do you think are important as a robotics engineer at Mujin?

As we are a software company, I would like to work with people who understand software development. At the same time, knowing robotics and liking robotics is a big plus.

Having good knowledge of linear algebra is important. We use simulations for development, and engineers should not question themselves about how to change the system of coordinates or represent the position in another object’s frame. We write software to work with real hardware, and people should understand the architecture of computers and have a basic level of understanding what’s happening, not just “I write code, I have no idea what’s happening after it runs.”

We are controlling robots in real-time. Before, we couldn’t achieve moving robots in real-time because we didn’t have enough computational power. Now it’s improving, but computational performance is never enough. Therefore, I also hire people who understand algorithmics and have strengths in data structure to write efficient and fast programs. We write optimized code and parallelize our computation often. That’s why I ask questions about parallel computations during the screening process.

It’s OK not to know everything. Engineers are constantly learning. We evaluate people based many criteria, and we think that some skills could compensate for others. We are trying to find people whom will be a fit for our needs and whom will benefit from working with us. Ours a very hard area for software development; industrial automation is very complicated.

The quality we expect is super high and we need passionate people who never give up. That’s the only way to achieve innovation.

– Our seven company values have always played a fundamental role. Which value in particular is a perfect representation of the Mujin culture?

All of them. I fully agree with all seven values, and they all represent our company (Mujin is proud to announce our Vision and Core Values). That’s why I’m here.

I like some values a little more, like “Never give up, never surrender” or “Understand the big picture”. You cannot just isolate yourself in your room and focus on one task; that’s not how robotics works. One person cannot do robotics alone. Also, I like “Be crazy about your job” because our job is crazy and sometimes it makes you crazy.

People who love and enjoy their job are the strongest.

Mujin has grown to become the first company in the world to realize the motion planning and industrial robots in live commercial scenarios, and we are continuously striving to accomplish our vision to “Liberate humans from manual labor to make them focus on creativity, innovation, and making the world a better place.” Mujin culture is the way we are going to achieve our vision and our goal. We are an international company and we are lucky to have positive contributions from different viewpoints and different nationalities. It’s important to embrace each other and our differences. We are united by the same goal and that’s what makes Mujin a strong company.

– What is the Future of robotics?

Mujin.

In the future, I would like to send ingredients (like package kits) to the factory and then receive a ready-made product without going inside. As soon as we can achieve such a future, it will boost our economy and our efficiency by a lot. Humans will be liberated for more creative and useful projects such as protecting the environment, traveling to space, and discovering new worlds.

If you are interested in being a part of the Robotics System team, please apply directly through our career website.

Robotics is the Future – Engineer Interview: